Your Joining deck boards end to end images are ready. Joining deck boards end to end are a topic that is being searched for and liked by netizens now. You can Get the Joining deck boards end to end files here. Download all royalty-free photos.

If you’re looking for joining deck boards end to end images information linked to the joining deck boards end to end keyword, you have visit the right blog. Our site frequently gives you suggestions for viewing the maximum quality video and image content, please kindly surf and locate more enlightening video content and images that fit your interests.

Joining Deck Boards End To End. Cut crown-molding ends on opposite sides of the blade for a tight end-to-end joint. In a butt join installation the distance from the screws to the end of the board is about 15 max in the case as illustrated here the screw is about 20 to 25 in from the end of the top board. In this installment I show you how I cut off the deck board ends from my new floating deck and round over the cut edgeBLOG. Sistering joists is commonly used when adding onto an existing deck or repairing a deck.

With The Wooden Pallet One Can Make Many Items But For Making These Items One Should Know The Best Tact Wood Table Diy Outdoor Wood Projects Diy Kitchen Table From pinterest.com

With The Wooden Pallet One Can Make Many Items But For Making These Items One Should Know The Best Tact Wood Table Diy Outdoor Wood Projects Diy Kitchen Table From pinterest.com

Usually you would split the wood if. Now push them together end to end. This U should open downwards with outward arching slants traveling down. This video is part of my ebook Love Your Deck. Ripp the jasmin out as It takes up 1m of that side and make the deck go to the fence either side. Step 1 Arrange and Mark the Boards.

Step 1 Arrange and Mark the Boards.

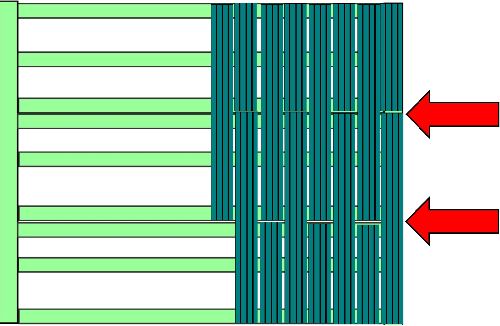

With a wide deck and a random arrangement of board ends this adds a lot of parallel joists. The curve would come out from where the deck is now roughly to curve out to the pots. Usually you would split the wood if. Im trying to figure out if I have a valid construction concern or if Im just being neurotic. And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine. Fit a square dowel into the hole in the middle then pound it in with a mallet closing the remaining gaps.

Source: woodworkmag.com

Source: woodworkmag.com

The longer the overlap distance the stronger the connection. So the book suggests having a parallel joist separated by a 12 spacer to screw the next board in line to. It will be hard to push them all the way in but once they are over the lip the joint is ready for the final step. Step 1 Arrange and Mark the Boards. In these cases the overlapped joists help tie the framing together by combining the rigid members over a beam.

Source: plasticinehouse.com

Source: plasticinehouse.com

Step 1 Arrange and Mark the Boards. Cut crown-molding ends on opposite sides of the blade for a tight end-to-end joint. To join the halves clamp the lower one against a flat surface. In these cases the overlapped joists help tie the framing together by combining the rigid members over a beam. An easy and invisible option of joining two boards together is by using a dowel joint.

Source: pl.pinterest.com

Source: pl.pinterest.com

Position the doweling jig over the top of the mark and start drilling your holes. An easy and invisible option of joining two boards together is by using a dowel joint. Want your new deck to last twice as long as others. The only other trick to applying the decking is to drill pilot holes when nailing near the end of a board. Going crazy keeping your current deck stained.

Source: plasticinehouse.com

Source: plasticinehouse.com

Depending on the magnitude of damage it may be better to remove the. Want your new deck to last twice as long as others. If your among the thousands of men who dont have long enough wood you have to see this. The longer the overlap distance the stronger the connection. An easy and invisible option of joining two boards together is by using a dowel joint.

Source: industrydiy.com

Source: industrydiy.com

Im trying to figure out if I have a valid construction concern or if Im just being neurotic. Ripp the jasmin out as It takes up 1m of that side and make the deck go to the fence either side. This involves areas such as where two deck boards join together in the center of a joist and both ends must be nailed to that joist. An easy and invisible option of joining two boards together is by using a dowel joint. Sandwich the replacement between two sisters of equal dimensional lumber that extend two or more feet past each end of the cutout.

Source: pinterest.com

Source: pinterest.com

Now push them together end to end. It will be hard to push them all the way in but once they are over the lip the joint is ready for the final step. The longer the overlap distance the stronger the connection. You may need to install temporary supports to hold and align the cut joist. The curve would come out from where the deck is now roughly to curve out to the pots.

Source: wikihow.com

Source: wikihow.com

This U should open downwards with outward arching slants traveling down. The curve would come out from where the deck is now roughly to curve out to the pots. This video is part of my ebook Love Your Deck. With a wide deck and a random arrangement of board ends this adds a lot of parallel joists. It seems the standard method for building decks is to just randomize the ends as much as possible butt the boards on a.

Source: pinterest.com

Source: pinterest.com

What you need to do to achieve this one is to butt the pieces and mark the dowel positions accordingly. Once youre happy with the aligned boards appearance draw a wide U shape with the chalk across the aligned boards. And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine. In this installment I show you how I cut off the deck board ends from my new floating deck and round over the cut edgeBLOG. Depending on the magnitude of damage it may be better to remove the.

Source: diy.stackexchange.com

Source: diy.stackexchange.com

To cut out a damaged section back-out fasteners from deck boards above it remove and replace it with similar dimensional wood. Position the doweling jig over the top of the mark and start drilling your holes. The curve would come out from where the deck is now roughly to curve out to the pots. Fit a square dowel into the hole in the middle then pound it in with a mallet closing the remaining gaps. You should overhang at least a couple of feet on each side of the beam.

Source: pinterest.com

Source: pinterest.com

To cut out a damaged section back-out fasteners from deck boards above it remove and replace it with similar dimensional wood. Sistering joists is commonly used when adding onto an existing deck or repairing a deck. It will be hard to push them all the way in but once they are over the lip the joint is ready for the final step. And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine. Then clamp the upper piece down and against the bevel on the lower piece.

Source: pinterest.com

Source: pinterest.com

And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine. First place down your selected boards on a flat workspace. Fit a square dowel into the hole in the middle then pound it in with a mallet closing the remaining gaps. But in all seriousness youll learn to connect to pieces of identic. Depending on the magnitude of damage it may be better to remove the.

Source: pinterest.com

Source: pinterest.com

Going crazy keeping your current deck stained. No squaks if you use screws. In these cases the overlapped joists help tie the framing together by combining the rigid members over a beam. In this installment I show you how I cut off the deck board ends from my new floating deck and round over the cut edgeBLOG. And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine.

Source: pinterest.com

Source: pinterest.com

An easy and invisible option of joining two boards together is by using a dowel joint. What you need to do to achieve this one is to butt the pieces and mark the dowel positions accordingly. This involves areas such as where two deck boards join together in the center of a joist and both ends must be nailed to that joist. Arrange them as desired so that their wood grains and shades match effectively. So the book suggests having a parallel joist separated by a 12 spacer to screw the next board in line to.

Source: pinterest.com

Source: pinterest.com

And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine. Arrange them as desired so that their wood grains and shades match effectively. So the book suggests having a parallel joist separated by a 12 spacer to screw the next board in line to. Going crazy keeping your current deck stained. Then clamp the upper piece down and against the bevel on the lower piece.

Source: ultimatehandyman.co.uk

Source: ultimatehandyman.co.uk

With a wide deck and a random arrangement of board ends this adds a lot of parallel joists. And in a deck that is about 10 year old which I did back then the joints were fixed with galvanised deck nails and the joins are still all flat hardwood joists not pine. It seems the standard method for building decks is to just randomize the ends as much as possible butt the boards on a. Now push them together end to end. In these cases the overlapped joists help tie the framing together by combining the rigid members over a beam.

Source: pinterest.com

Source: pinterest.com

It seems the standard method for building decks is to just randomize the ends as much as possible butt the boards on a. In a butt join installation the distance from the screws to the end of the board is about 15 max in the case as illustrated here the screw is about 20 to 25 in from the end of the top board. If your among the thousands of men who dont have long enough wood you have to see this. No squaks if you use screws. This video is part of my ebook Love Your Deck.

Source: diy.stackexchange.com

Source: diy.stackexchange.com

You should overhang at least a couple of feet on each side of the beam. Joining two boards in a run When joining two cut deck boards together in a run fix with screws 15mm from the end of each board at an angle to ensure secure fixing into the joists below. It will be hard to push them all the way in but once they are over the lip the joint is ready for the final step. This U should open downwards with outward arching slants traveling down. In these cases the overlapped joists help tie the framing together by combining the rigid members over a beam.

Source: pinterest.com

Source: pinterest.com

But in all seriousness youll learn to connect to pieces of identic. Im trying to figure out if I have a valid construction concern or if Im just being neurotic. Going crazy keeping your current deck stained. This U should open downwards with outward arching slants traveling down. Now push them together end to end.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title joining deck boards end to end by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.